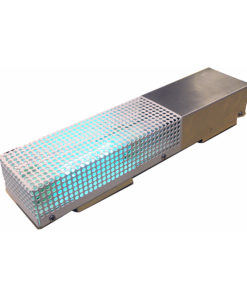

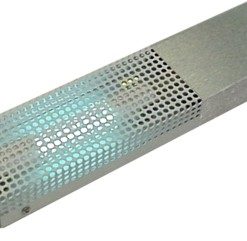

The Commercial PHI Unit by RGF® is designed to reduce odors, air pollutants, VOCs (chemical odors), smoke, mold bacteria and viruses. The unit is easily mounted onto air conditioning and heating system air ducts where most sick building and IAQ problems start. When the HVAC system is in operation, the PHI-Cell®technology creates an Advanced Oxidation Process consisting of Hydro-peroxides, super oxide ions and hydroxide ions. All are friendly oxidizers that revert back to oxygen and hydrogen after the oxidation of the pollutant. The system is fully assembled for easy installation.

Note: It is recommended these units be installed by a licensed electrician or HVAC contractor.